| Category: | Sampling |

|---|---|

| Brand: | HERZOG Maschinenfabrik Gmbh |

| Country: | Germany |

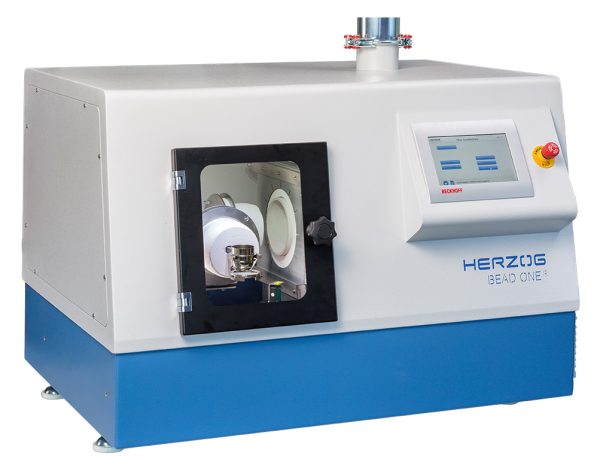

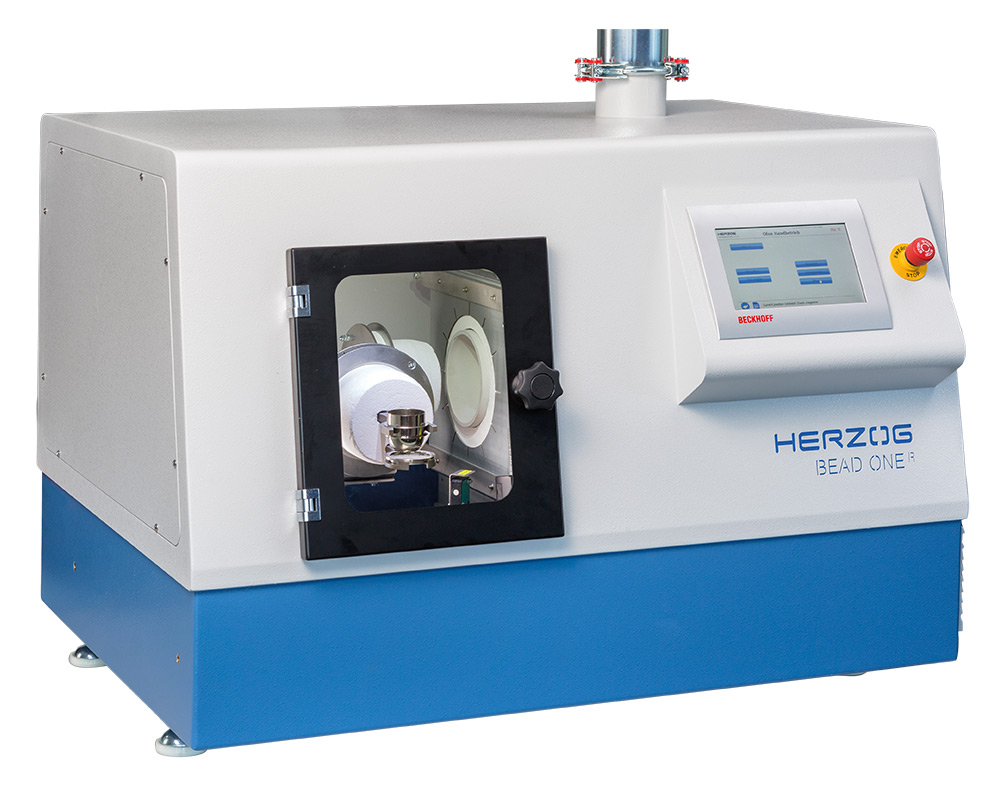

The benchtop fusion device with resistance heating technology- The compact and intelligent solution for your high analytical requirements

AREA OF APPLICATION

Use

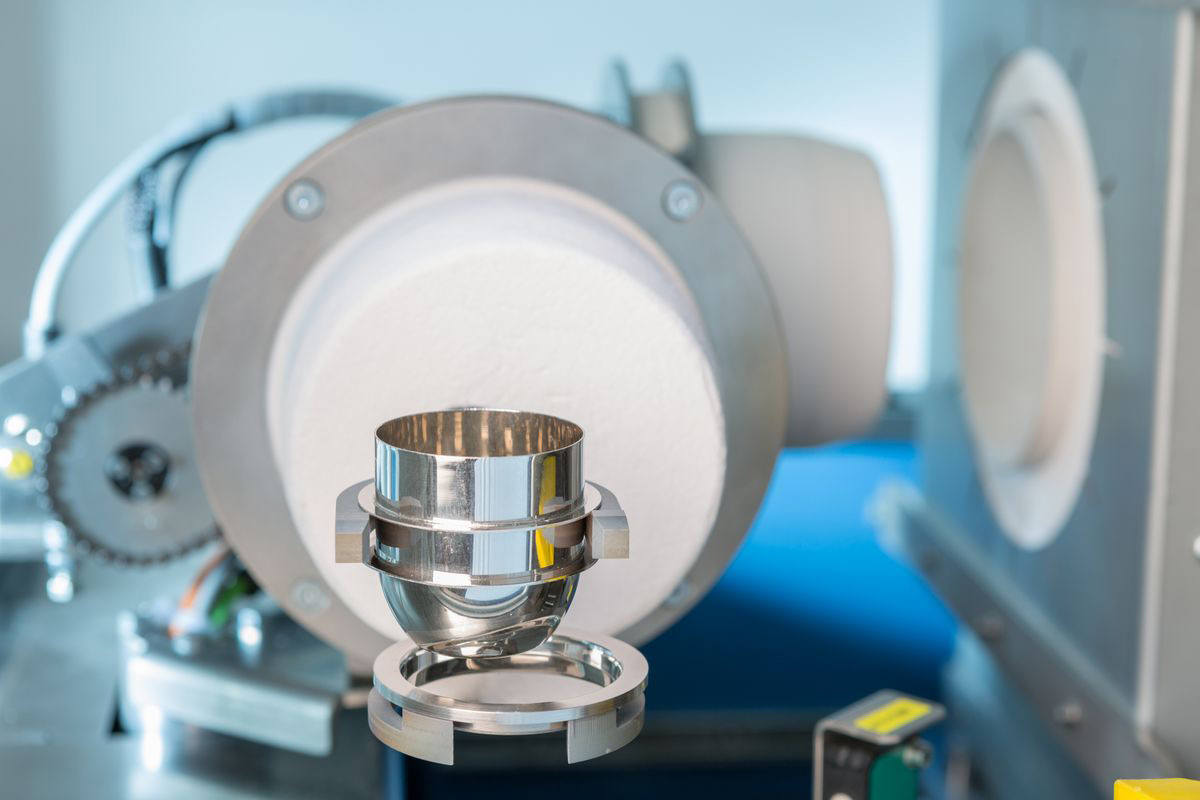

Preparation of fused beads (39 mm diameter) and analytical solutions

Material

Different oxidic sample material,e.g., cement, slag, ores, ferroalloys (feed size 200µm)

Operation mode

Semi-automatic

ADVANTAGES

Analytical Flexibility

The Bead One R combines highly repeatable and accurate analysis results with easy-to-use interfaces and maximum safety measures. Precisely controlled temperature and fusion parameters as well as the optional automatic magazine make the Bead One R to the future-proof instrument for your analytical excellence.

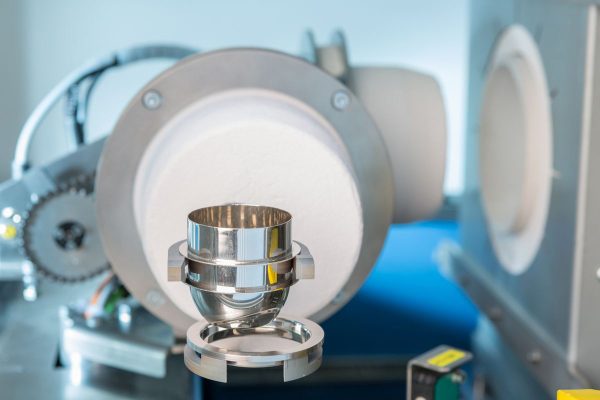

The Bead One R prepares glass beads for XRF analysis or borate or peroxide solutions for AA and ICP analysis. The fusion process can be exactly controlled by the parameters temperature, duration, heating rate and crucible rocking speed. After the melting process, the material can be either discharged into the casting dish or remain in the crucible until solid. Alternatively, the melt can be poured into acid solution cup which is positioned on a magnetic stirring device.

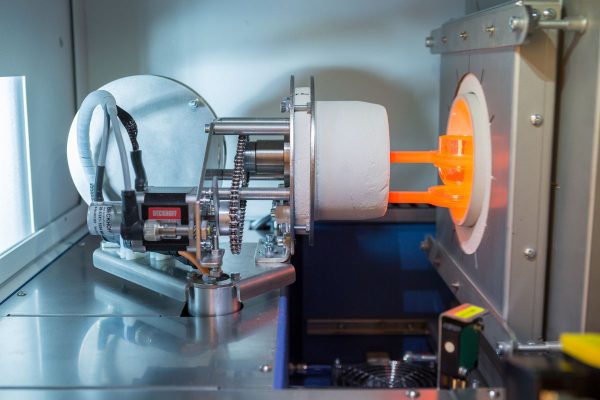

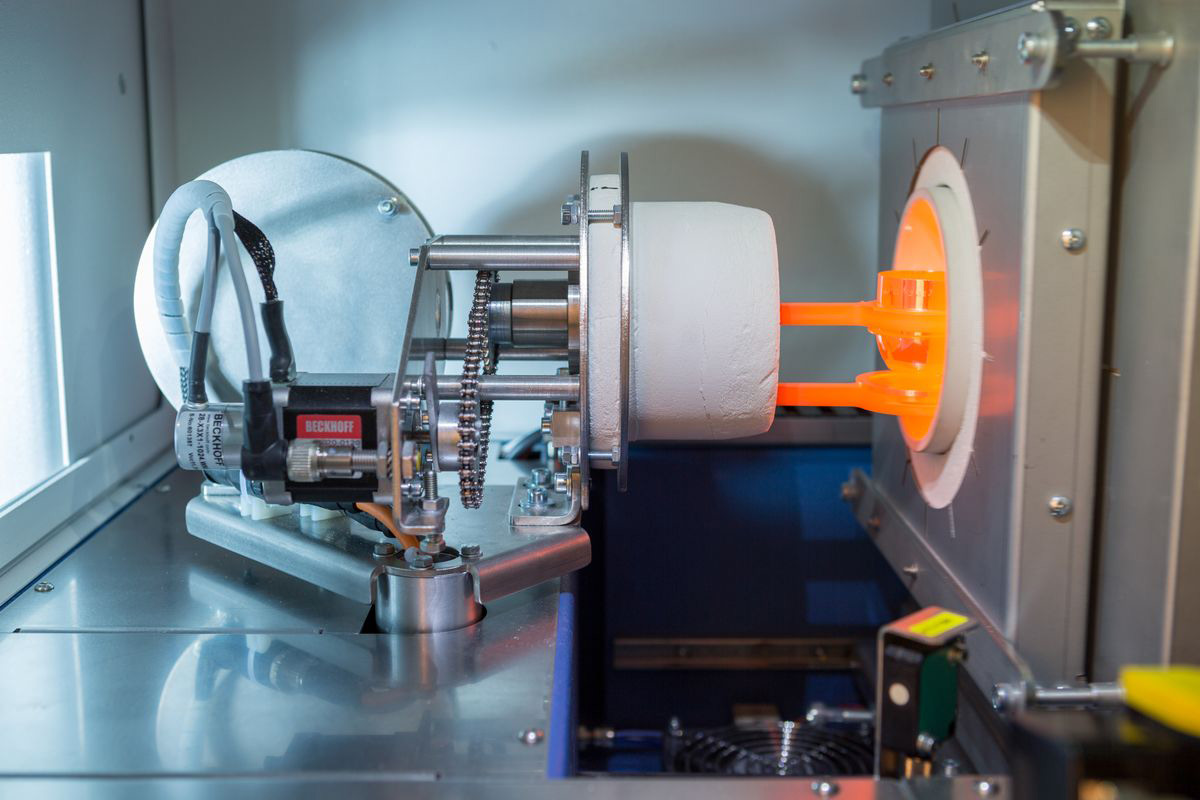

Heating Chamber

The tube furnace with a maximum operating temperature of 1350°C is made from high-quality components. The well-dimensioned high-grade SiC rods with heating from two sides guarantee uniform temperature distribution and high energy efficiency. The persistent PtRh-Pt thermocouple is located within the working tube for immediate temperature measurement. Wear-free and noiseless thyristors are used for very precise temperature control.

The multilayer furnace insulation consists of high-purity aluminum oxide sheets and allows for high-temperature shock resistance. The working tube is designed for the protection of machine components from aggressive vapors and is easily exchangeable.

User Interface

The clearly laid out HMI touchscreen provides you with a quick overview of operation mode and process parameters. The software comes with a set of 10 defined preparation methods. New recipes can be easily programmed, added and stored. For more efficient time utilization timers can be set for preheating and switch-off. TCP/IP and USB Interfaces allow the potential remote access to the instrument and data export for further analytical usage.

Safety

The safety door is locked during the entire fusion and cooling process. Pouring is fully-automatically without need for intervention. Therefore, the operator never comes into contact with hot vessels.

Magazine functionality

As an option, the Bead One R can be combined with a fully automatic magazine that can be easily retrofitted at a later date. The magazine has a capacity of up to nine crucibles and corresponding casting dishes. Samples are registered in desired order on the HMI of the Bead One R- no additional panel or control unit is needed. The handling system within the magazine automatically transports crucible and casting dish to the Bead One. After fusion, pouring and solidification of the melt crucible and casting dish are transferred to an extra cooling position and the Bead One is ready to accept a new sample from the magazine. When the vessels are completely cooled down they are transported to their magazine positions and can be removed by the operator for the analysis. The Bead One R magazine is designed for maximum safety. The safety door prevents operator’s interference with the magazine handling device. The covered extra cooling position guarantees a cool-to-cool operation.

OPTIONS

- Magazine (9 crucibles, 9 dishes)

- Casting position into liquid incl. Magnetic stirrer