| Category: | Sampling |

|---|---|

| Brand: | HERZOG Maschinenfabrik Gmbh |

| Country: | Germany |

The semi-automatic solution for cup wheel grinding of samples- Optimized technology for maximal flexibility, quality and cost-efficiency

AREA OF APPLICATION

Use

Grinding of of steel and pig iron samples for OES, XRF and other analytical procedures

Material

Steel and pig iron samples, different shapes and sizes according to clamping method

Operation mode

Semi-automatic

ADVANTAGES

Reproducible grinding for precise analyses

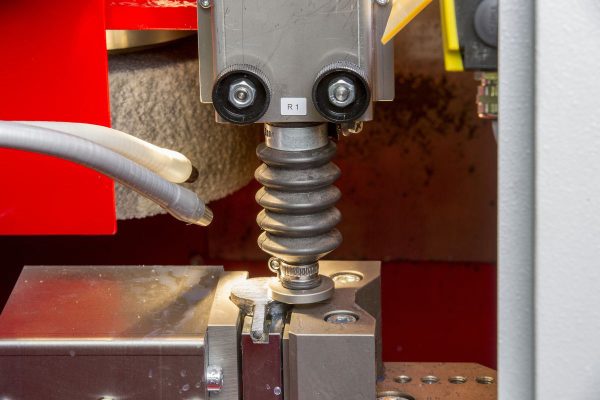

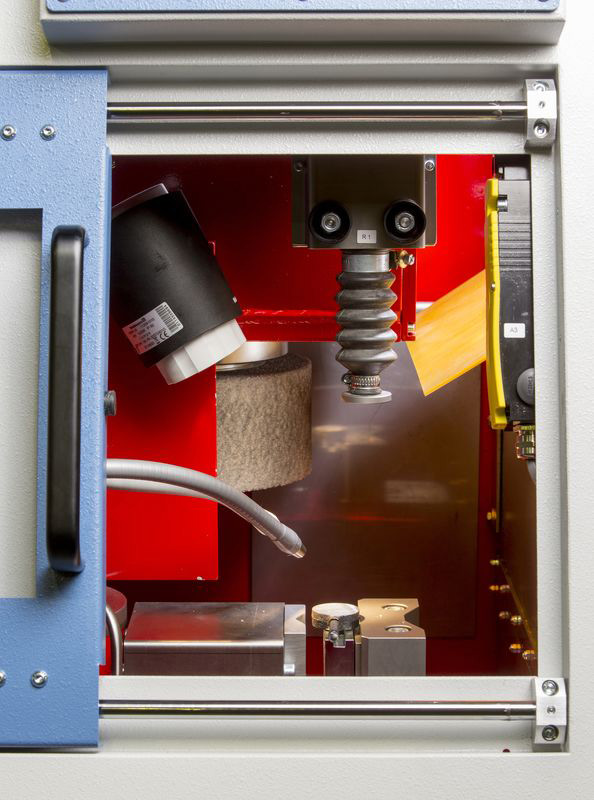

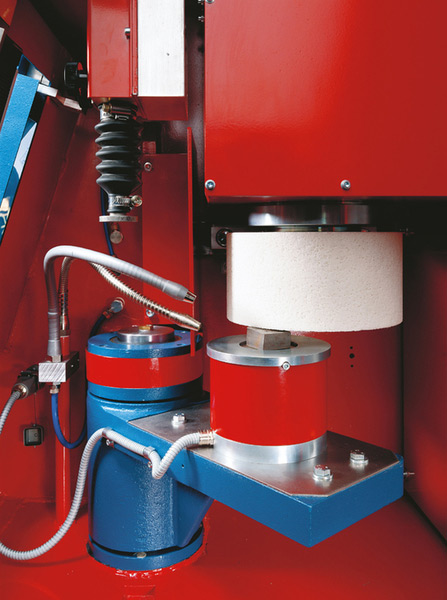

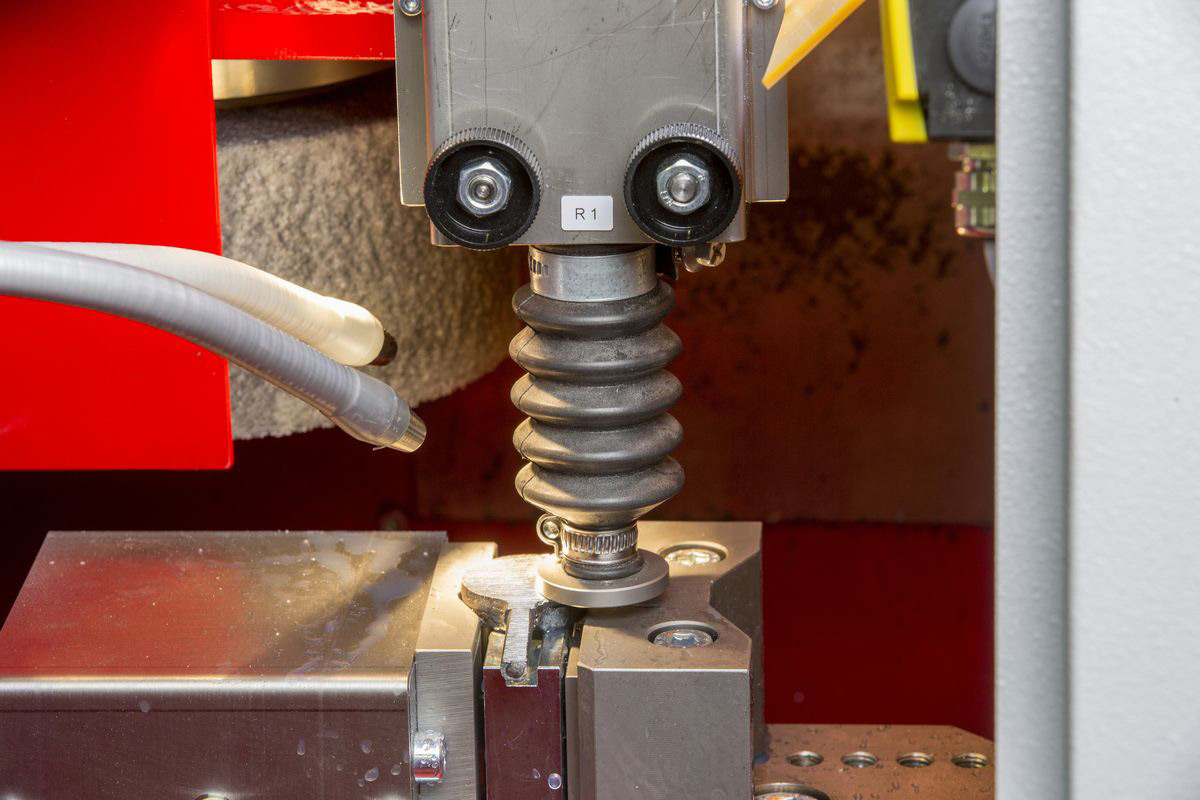

The HTS 2000 cup wheel grinding machine prepares iron and steel samples of all conceivable geometries for spectral analysis. The grinding process is controlled by a PLC control system. The reproducibility of sample preparation is improved considerably. The grinding support is driven by a servo motor. Cup wheel wear is monitored by a measurement facility. This ensures extremely precise grinding results in conjunction with short processing times and long service life.

The sample temperature may be up to 900°C. The sample is cooled during the grinding process with compressed air or by liquid coolant, depending upon the machine configuration. The tank for the cooling facility can be removed from the enclosure in a few simple steps for fast and straightforward cleaning.

Numerous options for different requirements

A hydropneumatic clamping fixture is available for clamping samples of any given geometry. An electromagnetic or permanent magnet clamping plate is available for use with magnetic samples. Cup wheels are available with a range of hardnesses and grains. This assures perfect adjustment to a range of different sample material.

PLC for precise, simple and safe grinding

All parameters required for sample processing are entered on an operator terminal. They can be saved and protected by a password. The subsequent operating cycles are then controlled automatically by the program controller. Maloperations are virtually impossible. Grinding results can be reproduced at any time.

The machine is fully enclosed and therefore generates low noise. It corresponds to the effective safety standards. A dust exhaust facility can be connected without difficulty as the machine is equipped with a connecting sleeve as standard.

OPTIONS

- Hydropneumatic clamping device (cylindric samples: diameter 32–55 mm, thickness 8–60 mm/ production samples: Length up to 70 mm, width: 32–55 mm, thickness 8–60 mm)

- Electromagnetic clamping device (magnetic samples with plane surface: Diameter 30–50 mm, thickness 4–60 mm)

- Liquid cooling device

- Demagnetizing device

- Dust collector