| Category: | Sampling |

|---|---|

| Brand: | HERZOG Maschinenfabrik Gmbh |

| Country: | Germany |

The complete solution- Specially designed and perfectly tuned technology for requirements of x-ray diffractometry

AREA OF APPLICATION

Use

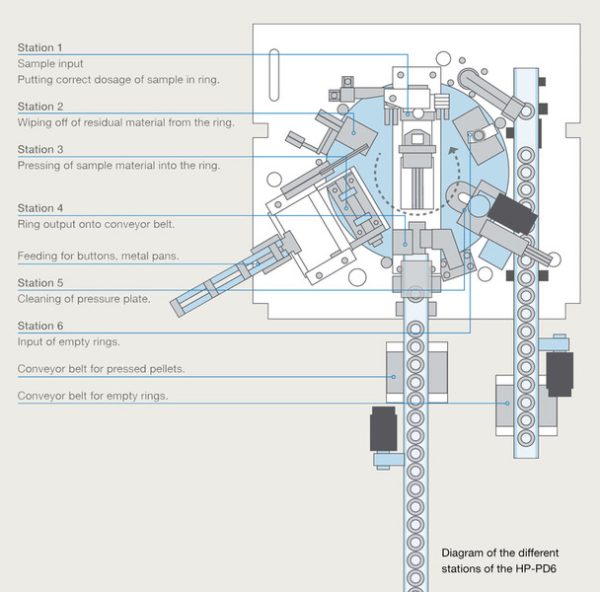

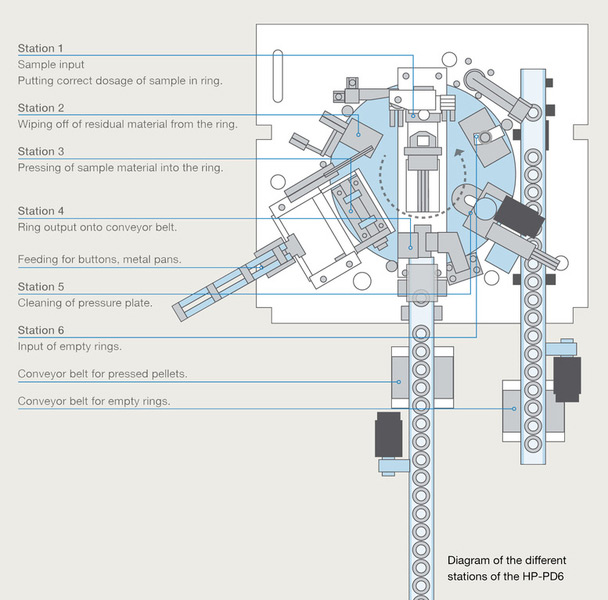

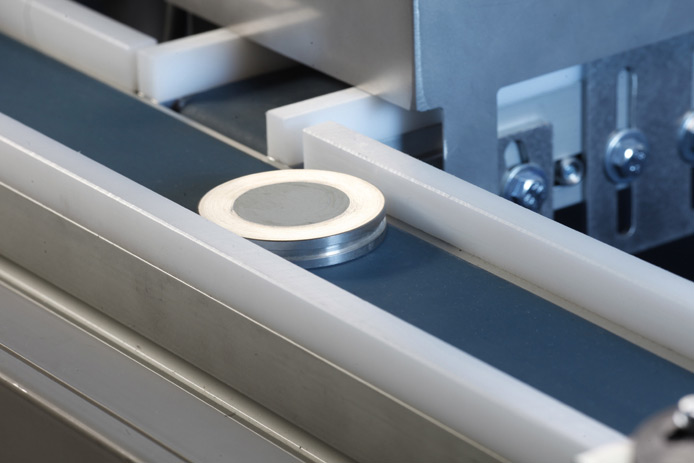

Preparation of pellets in steel rings (51. 5 mm diameter), backloading procedure for diffractometry

Material

Different materials, raw meal, clinker, cement, slag, ores, oxidic material, ferroalloys (feed size 100µm)

Operation mode

Automatic, standalone, standalone with magazine, linear automation, robot automation

ADVANTAGES

Special pelletizing process

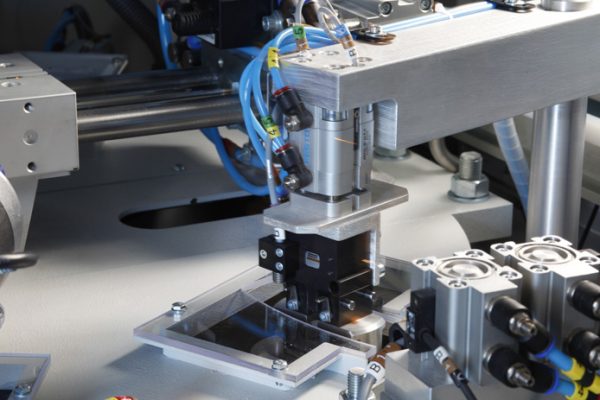

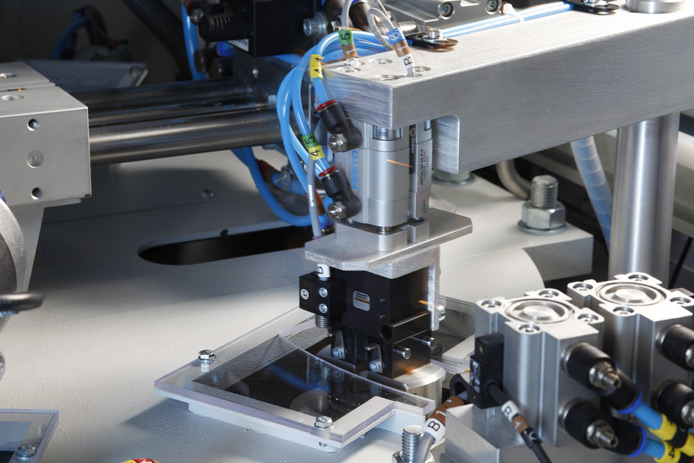

The pressing process is completely compatible with the requirements of the XRD analysis. Low pressing forces are applied so as to avoid any orientation of the crystals. The application of the back loading process ensures especially careful handling of the sample without any adverse influence on the surface to be analyzed. This guarantees accurate structure analysis results.

High throughput

The special design of the automation with simultaneous sample processing guarantees a high sample throughput whenever required.

Reproducibility, avoidance of contamination

HERZOG’s decades of experience combined with leading technology guarantee absolute precise reproducibility of the sample quality. The special focus on cleaning of relevant machine parts prevents contamination of subsequent samples.

Compact design, scalability

The compact design enables optimum use of space without restricting machine maintenance. All components of the HERZOG automation are perfectly aligned and thus ensure optimum analysis results. The automation can be individually adjusted to suit customer specifications and requirements.

Fully automatic connection to the analyzer

Almost all XRD analyzers produced by leading manufacturers can be easily connected to the HERZOG automation. ysis surface faces upwards and can be conveyed into the analyzer.

OPTIONS

- Loading magazine (30 to 300 cups)

- Output magazine for empty cups

- Automatic ring cleaning device