| Category: | Sampling |

|---|---|

| Brand: | HERZOG Maschinenfabrik Gmbh |

| Country: | Germany |

The standard for manual sample grinding- Efficiency and reliability for the high requirements of your laboratory

AREA OF APPLICATION

Use

Fine grinding of sample material for x-ray fluorescence spectroscopy, diffracotmetry and other analytical procedures

Material

Different materials, raw meal, clinker, cement, slag, ores, oxidic material, ferroalloys (feed size 5 mm)

Operation mode

Manual

ADVANTAGES

Manual Vibratory Disc Mill Model HSM

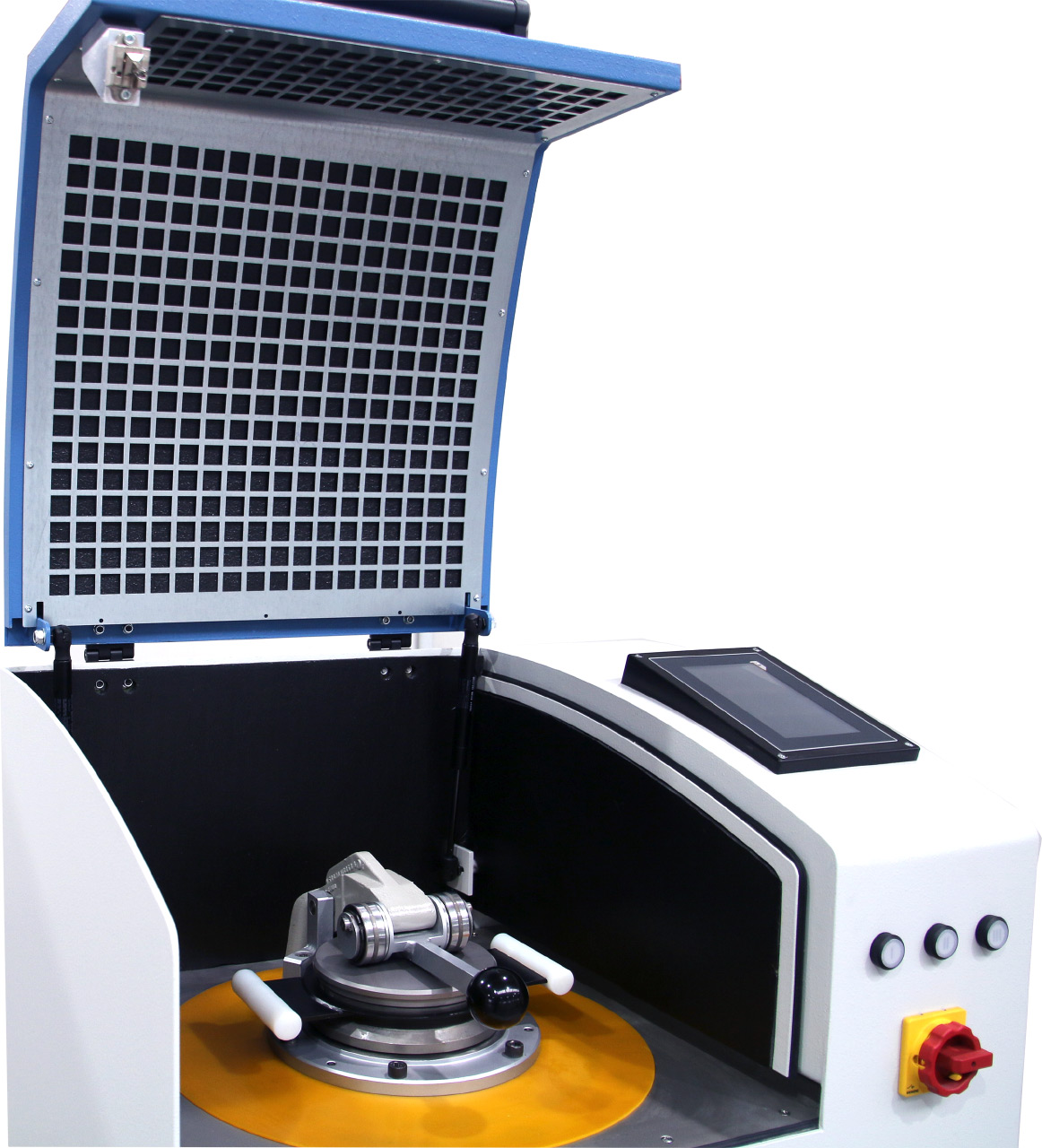

The HSM vibratory disc mill is the optimal machine for fine grinding of hard, medium-hard and brittle materials. The HSM provides highly efficient particle size reduction for a wide range of materials including mineral materials, slags, ferroalloys, and cement products. The simple and ergonomic operability, the low noise level and small footprint make it the optimal machine for laboratory operation. At the same time, the machine can be used in industrial environments without any problems due to its extremely robust and resistant design.

Maximum flexibility

The operator can easily configure all grinding parameters on the control panel of the HSM and compile individual sample preparation programs. The programmable logic controller allows up to 30 different program sequences to be stored. The speed of the mill is continuously adjustable in a range between 750 and 1500 rpm. The automatic program sequence guarantees reproducible sample preparation and thus a high degree of accuracy and precision in material analysis. Due to the high rotation speed, even hard materials are ground down to the required particle size within short preparation times.

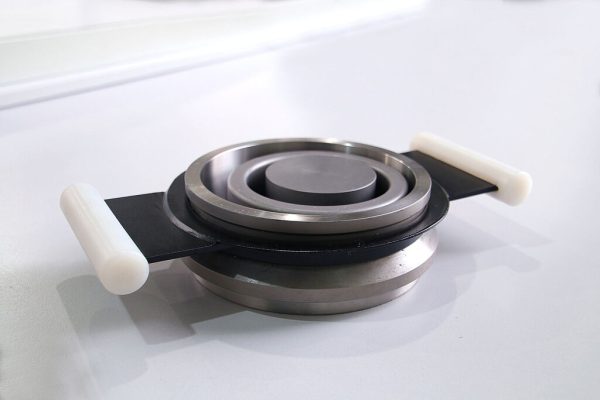

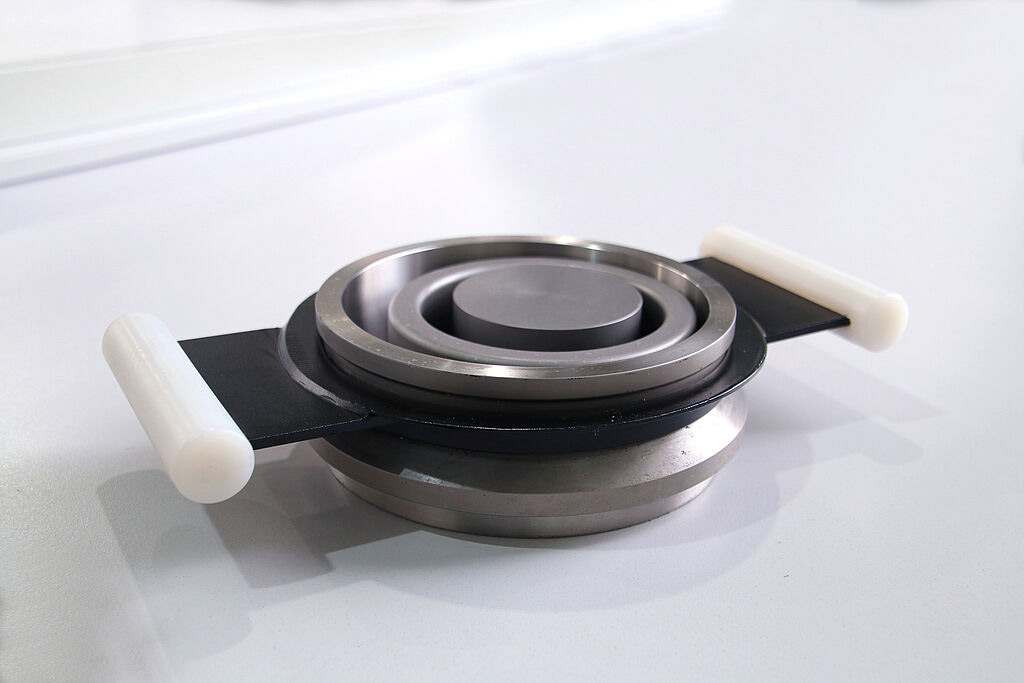

To enable analysis-neutral comminution of the sample material for different applications, grinding vessels and sets are offered in different material qualities. Optional versions are available in chrome steel, tungsten carbide, colmonoy and agate.

Various grinding vessel sizes are available for efficient grinding of different sample quantities. In the chromium steel and tungsten carbide version, grinding vessel volumes of 10, 50, 100 and 250 ccm are offered. In the Colmonoy version, grinding vessels with a volume of 100 or 250 ccm can be used. The respective grinding sets are adapted in such a way that an optimum grinding result is achieved with each grinding vessel size.

Great ergonomics and operability

A major focus was placed on the safe and ergonomic operation of the HSM. The working height has been adjusted to allow effortless loading and unloading of the grinding vessel. A broad carrying grip on both sides makes handling of the grinding vessel easier and leads to more comfort and safety during transport.

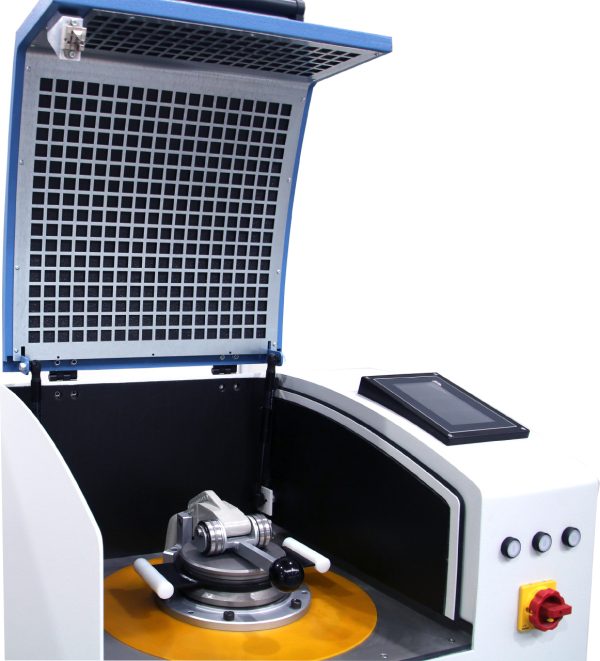

Accessibility to the machine has been further improved by enlarging the grinding chamber. The operator can open and close the machine door safely and comfortably with the help of the gas springs. During machine operation, access to the machine chamber is prevented by a safety switch with guard locking. The completely enclosed grinding chamber and the sound-insulating lining of the housing result in a significant noise reduction.

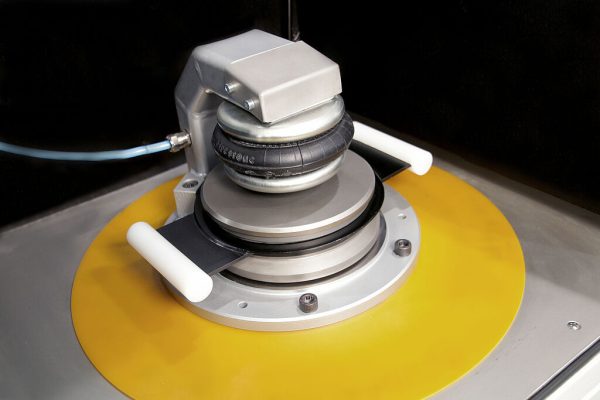

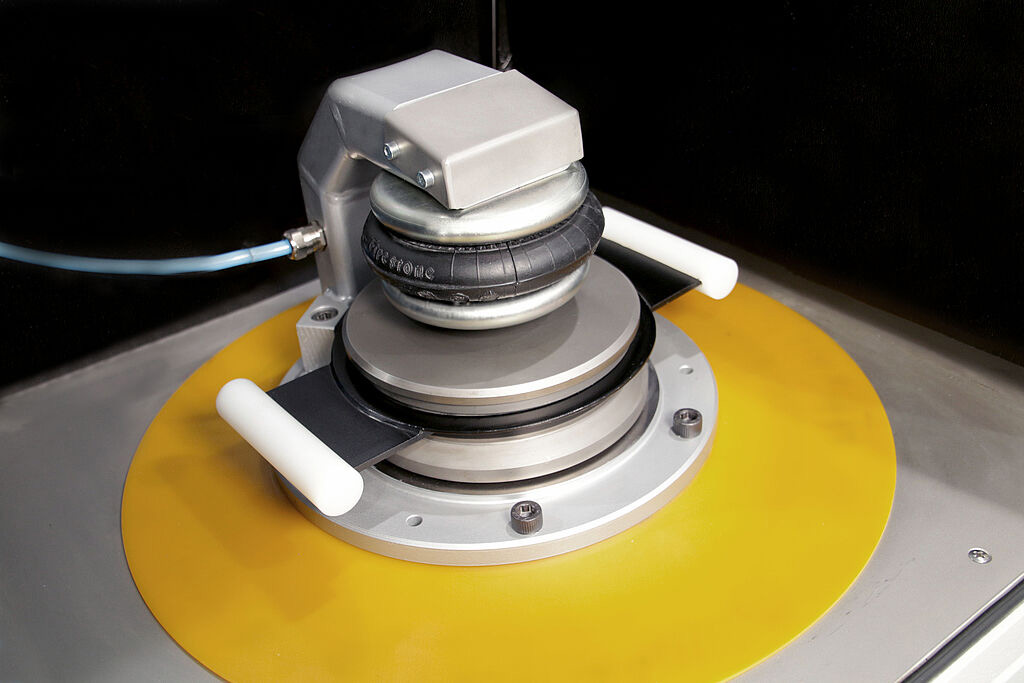

In the basic HSM-H variant, the grinding vessel is clamped by means of an easy-to-operate quick-action clamping device. In the optional HSM-P variant, the grinding jar is automatically fixed by a pneumatic clamping device.

The machine is operated by means of the integrated touch-sensitive 7-inch color display. The panel size and clear menu navigation allow easy and intuitive access to all machine functions. The three buttons placed on the front of the machine are programmable and allow the direct start of frequently used preparation programs.

Improved service properties

The HSM features improved maintenance and service characteristics. Optionally available machine feet enable the machines to be set up on uneven floors and allow easy adjustment to the operator’s optimum working height.

The front- and side-mounted inspection hatches facilitate access to the interior of the machine so that regular cleaning and inspection tasks can be performed easily by operators. In addition, any service and repair work that is required can be carried out quicky and efficiently.

OPTIONS

- Pneumatic clamping device (HSM-P)

- Grinding vessels and grinding set made of chrome steel (10, 50, 100 or 250 ccm)

- Grinding vessels and grinding set made of tungsten carbide (10, 50, 100 or 250 ccm)

- Grinding vessels and grinding set made of Colmonoy (100 or 250 ccm)

- Grinding vessel and grinding set made of agate (100 ccm)