| Category: | Sampling |

|---|---|

| Brand: | HERZOG Maschinenfabrik Gmbh |

| Country: | Germany |

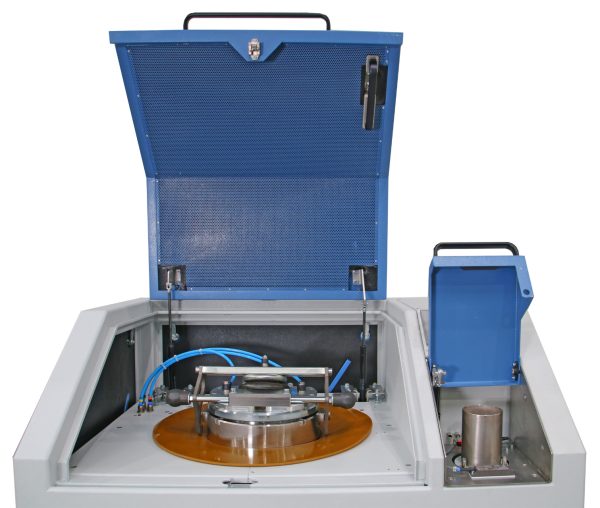

The optimum solution for semi-automatic grinding of large volume samples- Efficiency, robustness and quality for a wide range of applications

AREA OF APPLICATION

Use

Fine grinding of sample material for x-ray fluorescence spectroscopy, diffracotmetry and other analytical procedures

Material

Different materials, raw meal, clinker, cement, slag, ores, oxidic material, ferroalloys (feed size 5 mm)

Operation mode

Semi-automatic, standalone, standalone with magazine, linear automation, robot automation

ADVANTAGES

Specially designed for large sample volumes

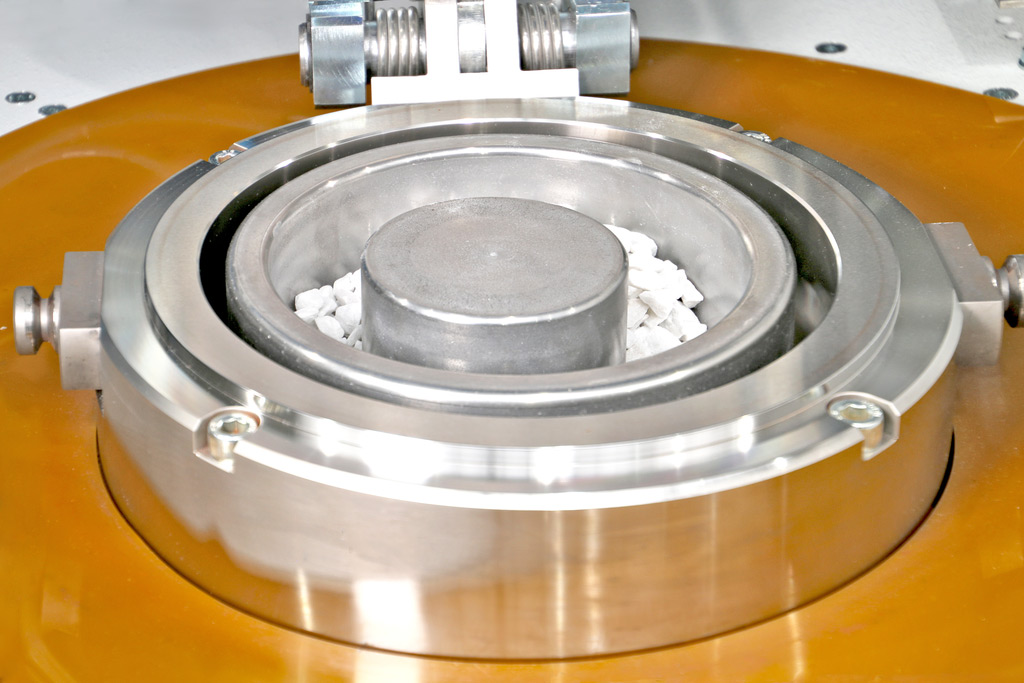

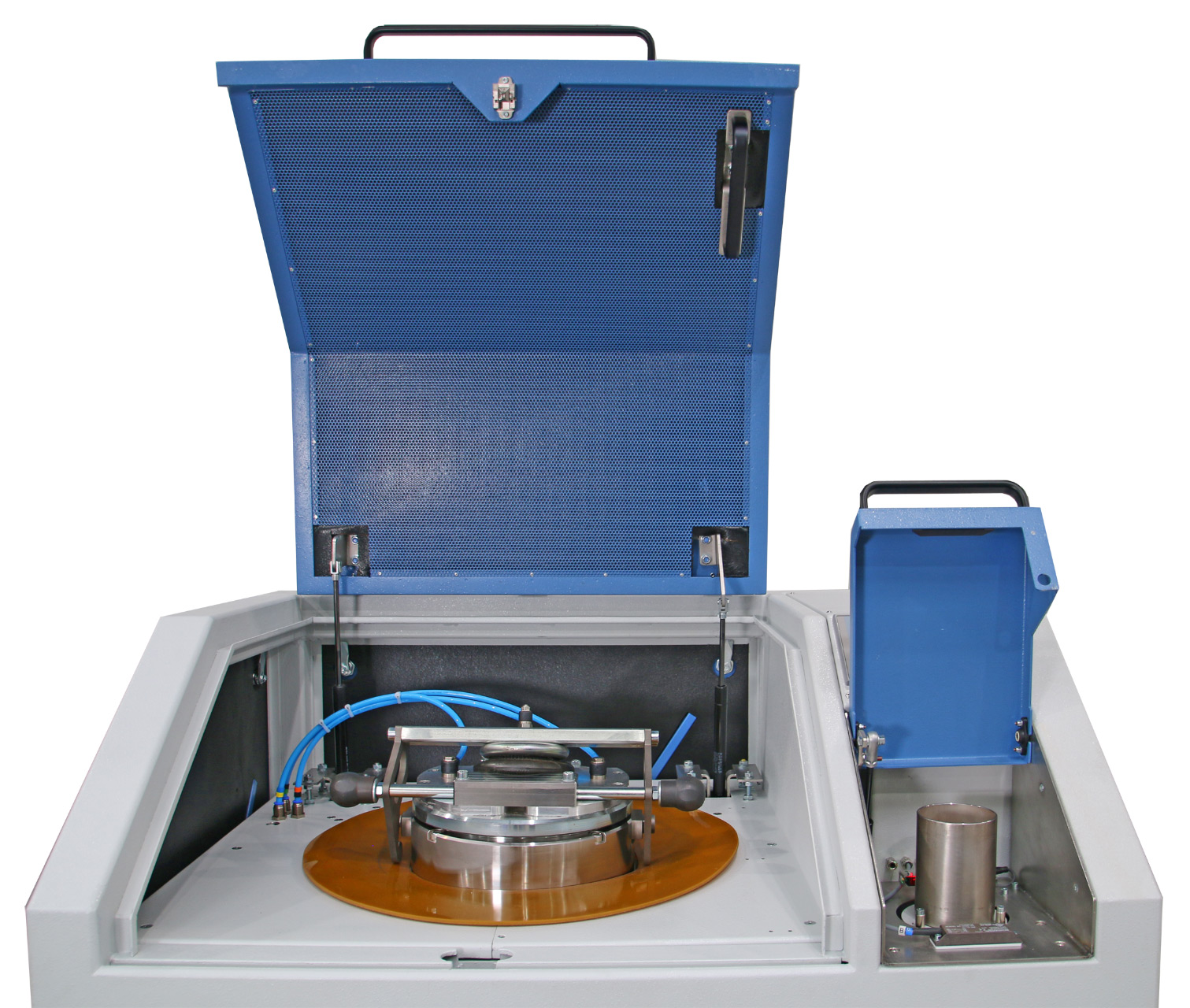

The HP-M 500 is the disc grinding mill especially designed for pulverizing of large material volumes. The machine can be equipped with an exchangeable 500 or 1000 ccm grinding vessel made from chrome steel. The HP-M 500 enables automation of strenuous and time-consuming preparation steps including filling of ground material into the sample cup and cleaning of the grinding vessel. This significantly improves labor safety, lowers physical stress of the laboratory staff and increases reproducibility of sample preparation and analysis.

Wide range of applications

The HP-M 500 is suitable for a wide range of material like, e.g., minerals, slags and ferroalloys. The rotation speed of the grinding vessel is continuously adjustable between 600 and 1500 rpm and allows optimal adaptation to the specific characteristics of each sample material. The choice between 500 and 1000 ccm vessels gives the operator ample flexibility to implement almost any application. The grinding vessels Ein can be easily exchanged and mounted on the swinging aggregate.

User-friendly operation

Great deal was set in user-friendly operation of the machine. The machine cover has an external and internal handle for easy opening and closing. Lifting and lowering of the cover is virtually effortless due to the support by gas pressured springs.

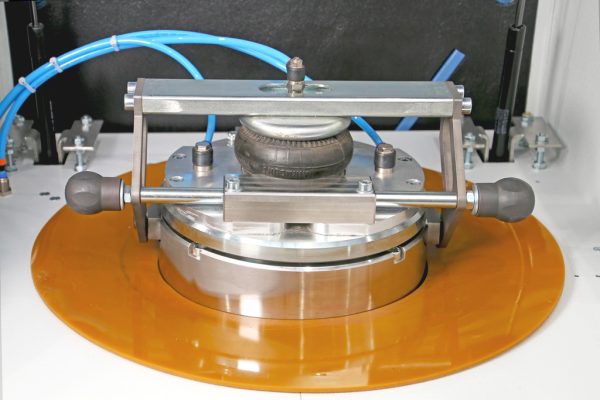

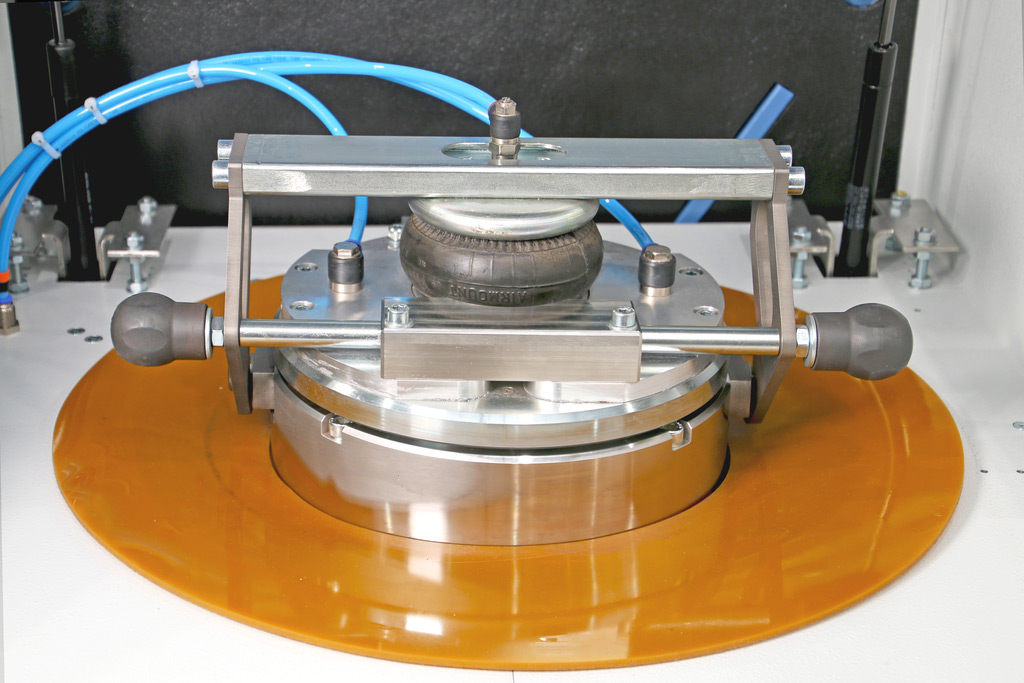

With equal ease, the operator can lift the lid of the grinding vessel due to an integrated robust spring mechanism. This makes filling the sample into the grinding vessel very simple for the laboratory personnel. After starting the program on the HMI panel the grinding vessel is automatically locked by a pneumatic cylinder.

After completion of the pulverizing process, the grinding vessel is automatically evacuated via the bottom valve. The ground material is filled into a sample cup which can be removed from a separate output position. In the meanwhile, the grinding vessel is automatically cleaned by compressed air to be ready for the next grinding action.

Increased efficiency and reproducibility

The HP-M 500 eliminates lengthy and arduous manual operations leading to significantly increased laboratory efficiency and sample throughput. Concurrently, the automation involves higher reproducibility of the sample preparation process and less bias in the analysis results.

Improved labor safety and maintenance

Due to the automated discharge of the sample material it is no longer necessary to remove the heavy grinding vessel from the machine. This is an important condition to reduce potential safety risks and decrease the physical workload of the operator. Furthermore, it leads to a lower dust exposure in the workplace.

The HP-M 500 is fully encapsulated, insulated against noise and has a protective switch on the machine door. The emergency stop leads to immediate disconnection of power to the machine. The serviceable machine components including the swinging aggregate are easily accessible leading to simple and fast maintenance and service works.