| Category: | Sampling |

|---|---|

| Brand: | HERZOG Maschinenfabrik Gmbh |

| Country: | Germany |

Semi-automatic Milling Machine for preparation of steel samples

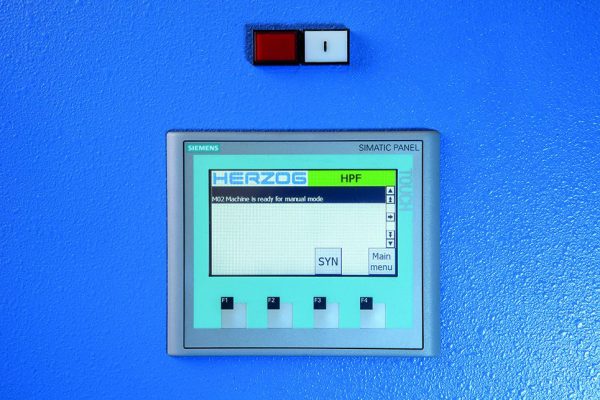

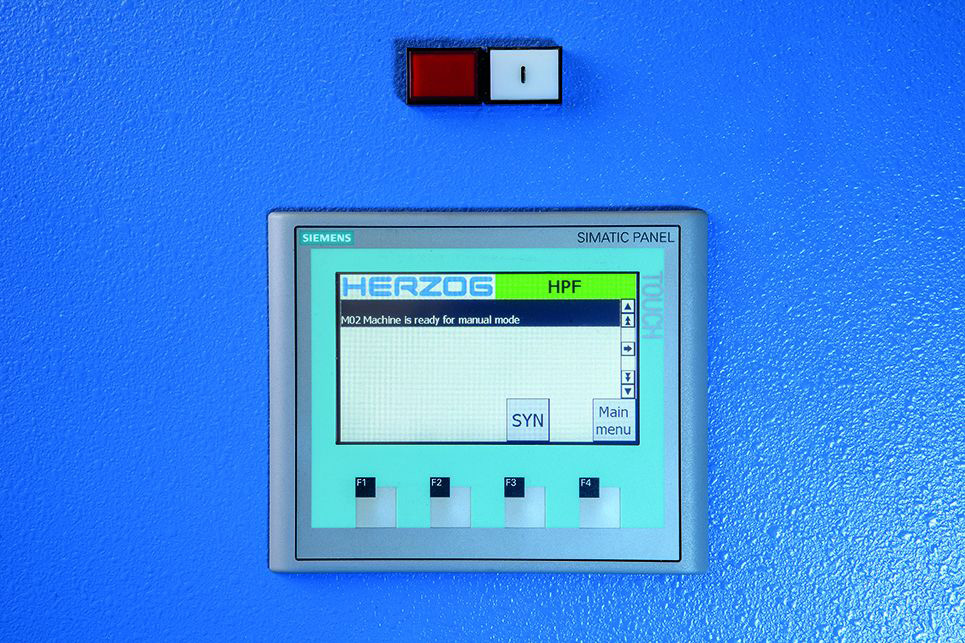

Automatic Operating Sequence

Milling depth, feed rate and spindle speed can be preselected. The milling depth is repeated without renewed setting, even on samples of different height. When the sample has been inserted into the clamping device and the machine is started, the operating cycle is accomplished automatically.

Short Machining Times

The sturdy design and high drive rating of the machine permit spindle speeds and feed rates right up the load limits of the reversible carbide tips. This means that the machining times can be kept extremely short. Two opposed hydraulic cylinders advance the milling spindle towards the sample and back to its starting position at rapid traverse speed.

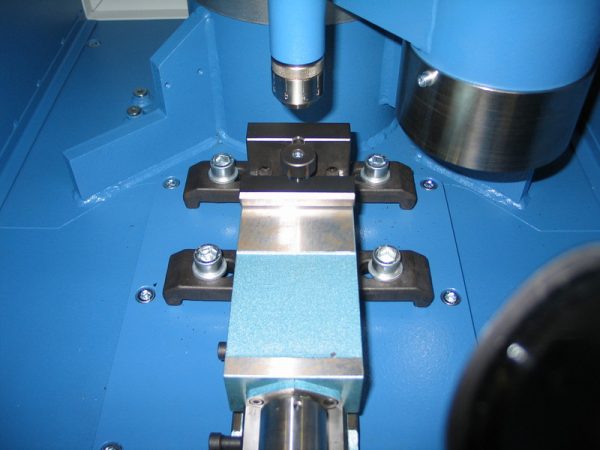

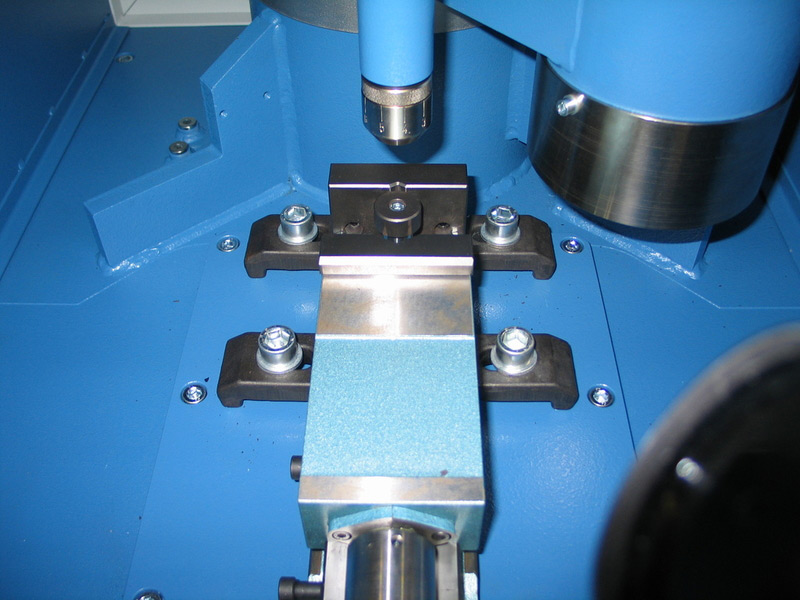

Reproducible Sample Surface

Top-quality sample surfaces are obtained as a result of steplessly variable milling spindle speed and miller feed rate. The exact repetition of the preset milling conditions for all samples guarantees excellent reproducibility of the sample surface

Safe Sample Operation

The machine is completely enclosed and requires only a minimum of operation and maintenance. The milling process can be observed through the window in the machine cover. When the cover is opened, a safety switch automatically de-energizes the machine. The cover can be opened on both sides of the machine column, meaning that the chips can be easily removed.

Operation Sequence

- With the safety cover open, the sample is inserted into the clamping device, then the cover is closed and the machine starts.

- Three different milling speeds can be preselected by switch. The feedrate can be simply adjusted by a regulator.

- If the special adjusting and clamping device is used, the sample is automatically aligned with the sample surface parallel to the miller. Then the sample is clamped and the milling process begins. The miller rapidly advances to the sample and machines the sample at the desired speed.

- Following completion of the milling process, the sample automatically returns to its starting position at rapid traverse speed. The clamping device automatically opens and the sample can be removed.

- When using the hydromechanical vice, the sample must be clamped by turning the vice spindle once. The milling procedure can then be started.

- With standard milling condition settings, the entire process takes about ten seconds for samples made of steel grades suitable for milling.