Innovative solutions

for industrial and

research laboratories

- Equipment

- IT solutions

- Analytical support

- Training

What we do

Making an error while analyzing or testing a material can lead to disastrous consequences during research, mining or production processes. These errors can come from various stages including sampling, sample preparation and analysis.

There is a constant need to optimize the speed and reliability of the quality control data, requiring effective sampling systems, advanced laboratory equipment and process control solutions.

To reduce costs and optimize your quality control, ECALab provides a full range of manual and automated solutions and information systems including sampling, sample transportation, preparation, analysis and data transfer.

Optical Emission Spectrometers

Optical Emission Spectroscopy, or OES, determines the elemental composition of solid metallic samples. OES combines high accuracy and low detection limits (<0.0001%) with high speed of analysis (~20 seconds). Main OES applications are: ferrous and non-ferrous metallurgy and all kinds of metal treatment as machine-building, e.g.

X-Ray Spectrometers

X-Ray Fluorescence (XRF) determines the elemental composition of all kind of samples (solids, liquids, powders) excluding gases. Depending on application wide range of XRF instruments includes portable, desktop and floortop spectrometers.

Main XRF applications: ferrous and non-ferrous metallurgy, cement, (petro-)chemical industry and science.

XRF elemental range from Be to U and concentration range is from 0.0001% to 100%

Powder X-ray diffractometers

X-Ray Diffraction (XRD) determines phase (or mineral) compostion of crystalline materials. In others words, XRD shows how elements are combined with each other.

XRD instruments are suited for phase identification, quantification, crystal structure analysis, Rietveld analysis, transition phase identification, and thin-film analysis.

Main XRD application: science, cement, metallurgy.

Sample preparation equipment

The analysis begins with the selection and preparation of a sample. Sampling and sample preparation depend on the nature of the analyzed object and on the method of measuring the analytical signal. The methods and procedure for sampling and its preparation are strictly regulated by regulatory documents. Sample preparation is very important, along with sampling it makes up to 95% of total error of analysis.

- Crushing

- Milling

- Pulverizing

- Grinding

- Fusion

- Pelletizing

Materials testing

- Tension

- Compression

- Bending

- Torsion

- long-term creep and stress-rupture

- Impact

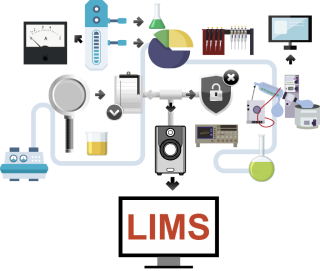

LIMS Limsan – Laboratory

Information Management System

A Laboratory Information Management System (LIMS) is software that allows you to effectively manage samples and associated data. By using a LIMS, your lab can automate workflows, integrate instruments, and manage samples and associated information. Additionally, you can produce reliable results more quickly and can track data across experiments to improve efficiency. We offer guidance to labs on selecting a LIMS. which suits their needs These include the key features to look for, considerations around the types of instruments you’ll need to integrate, budgetary requirements etc.

Support

Installation

Service

Guarantee

Maintenance and repair

Instrument selection depending on application

Analytical support

Training:

- Individual

- Group

Automated systems perform

one or several stages of quality

control without human participance

Sampling, transportation, preparation,

analysis of samples, LIMS